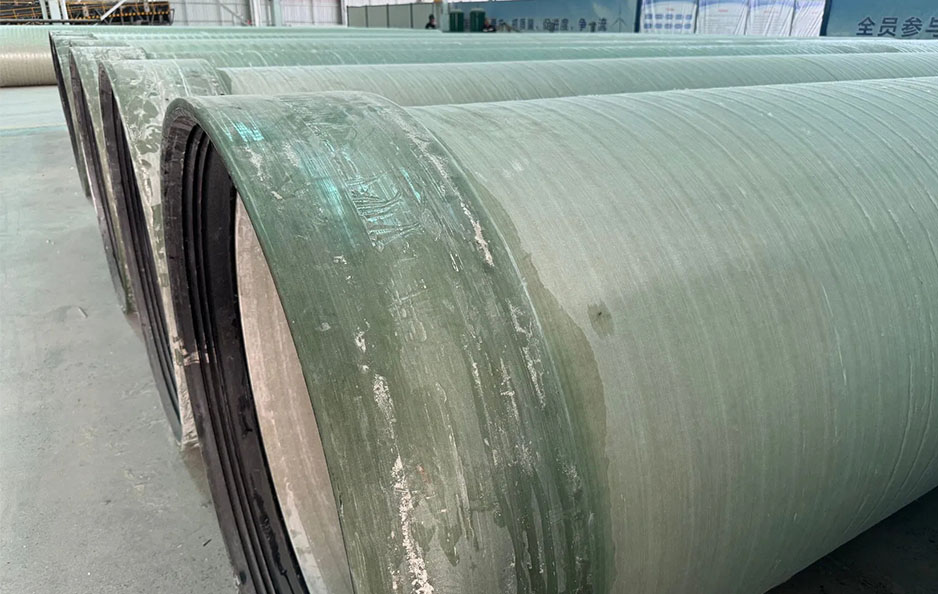

Glass Reinforced Plastic (GRP) pipes are manufactured using the Continuous Filament Winding (CFW) process. Our GRP pipe product range offers structural strength and corrosion resistance for optimum performance in high pressure applications. FRP are lightweight, extremely strong, easy to install, and resistant to deterioration.

Their resistance to the acidic environments of water and sewage systems is another advantage. Our GRP pipes are primarily used to transport drinking water, sewage drainage, and seawater, in addition to desalinated water, chemical and industrial residues, fire protection systems, cooling systems, and irrigation. GRP pipes can be manufactured in custom diameters and any required length. This facilitates easy installation, especially in relining projects.

Product Advantages

Advantage s of the FRp pipe:

1. corrosion resistance: select different types of anti- corrosion lining resin, used in different environment of acid, alkali, salt, and various oils, seawater and organic solvents.

2. Lightweight , easy maintenance, durability.

3. Easy to install :FR ppip e lengt hha sn o technical limitations, but in consideration of the transport, pipe length is generally less than 12m, so that greatly reduce the quantity of joints, due to the light weight of FRP, pipe can also be installed by hand or light installation

equipment, easy and quick.

4. Good applicability: existing standard diameter of FRP Pipe is between 25mm-4000mm, long-term pressure bearing ability is generally less than 1.6Mpa, in accordance with the special needs of the users, the higher pressure of6.4Mp a is achievable.

5. High transmission capacity: pipe wal li s smooth N-s 0.0084. compare with traditional pipe which has same diameter, it has a higher flow capacity, so it can save pump energy and extend project life.

6. LOW Permeability: because of the good sealed connection and the longer length of each pipe, FRP Pipe hasa lower permeability than traditional pipe, thus greatly reducing the risk of both groundwater penetrate into pipe and media penetrate out and contamination environment.

7. Rigorous test standards: our company has advanced testing equipments, and strictly implements inspection standards to ensure product quality. The relevant standards: ASTM, AW WA, AS ME, etc.

8. Low cost and long life cycle: FRp products which have a long service life, basically not need maintenance, installation and transportation costs is very low.

Application scenarios

1.Municipal water supply and drainage: construction of urban drinking water/sewage pipeline network, with smooth inner walls to reduce head loss

2.Integrated pipe gallery: preferred for underground pipe network renovation projects as a substitute for cement/steel pipes

3.Petrochemical industry: transporting strong acid and alkali media (pH 2-12), temperature resistant to 150 ºC

4.Power system: power plant circulating water pipeline, high-temperature flue gas emission channel

5.Metallurgical industry: Corrosive gas dust removal and waste liquid treatment pipelines

6.Food: Aseptic grade tubing, compliant with FDA food contact standards

7.Desalination of seawater: Cross sea water pipeline network, resistant to salt spray corrosion with a lifespan of over 30 years

8.Agricultural irrigation: Lightweight farmland water pipes, resistant to soil chemical corrosion

Geothermal Engineering: Special Pipeline for High Temperature Fluid Transportation in Geothermal Wells